Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Sistemas telescópicos de garfo

Sistemas telescópicos de garfo

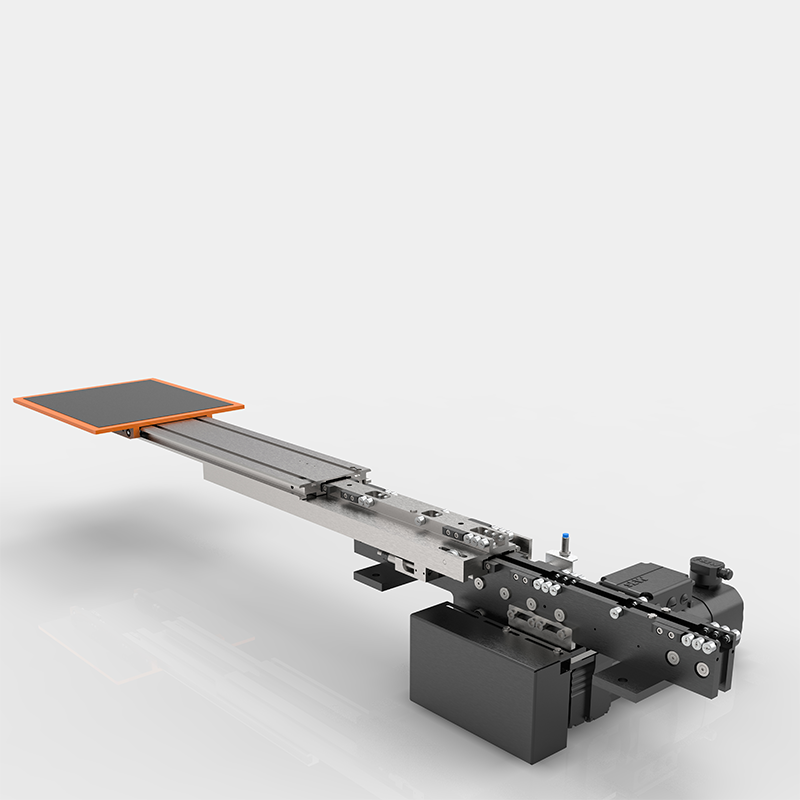

(2)Telescopic Fork Systems are a type of mechanical system designed to extend and retract the arms (or forks) used for lifting, carrying, and positioning heavy loads. These systems are primarily used in material handling and various industries where high reach or adjustable fork length is required. They are commonly used in equipment like telehandlers, forklifts, and cranes.

Key Features of Telescopic Fork Systems:

-

Extendable and Retractable: The most defining feature of a telescopic fork system is its ability to extend and retract the fork arms. This gives the operator flexibility in handling various load sizes or reaching different heights.

-

Adjustable Reach: With the telescopic function, operators can quickly adjust the fork length to handle materials at different distances or heights, improving the efficiency of lifting and positioning tasks.

-

Heavy-Duty Construction: Telescopic forks are designed to handle heavy loads, often made from durable materials like steel or high-strength alloys, ensuring long-lasting performance and reliability in demanding environments.

-

Space Efficiency: When not in use, the forks can retract, making these systems more compact and suitable for environments with limited space. This is particularly useful in warehouses, factories, or construction sites where storage space is a concern.

Applications of Telescopic Fork Systems:

-

Material Handling: Used for lifting, moving, and placing materials such as pallets, containers, or heavy equipment in environments like warehouses, distribution centers, and manufacturing plants.

-

Agriculture: Telescopic forks are used in agricultural equipment like telehandlers to move bales of hay, stack materials, or lift crops for processing.

-

Construction: In construction sites, these systems are essential for handling materials at varying heights and distances, such as lifting bricks, concrete blocks, and construction tools to different floors of buildings.

-

Logistics and Shipping: Telescopic forks help move large quantities of goods, especially in shipping and logistics operations where accessing different storage levels in containers is necessary.

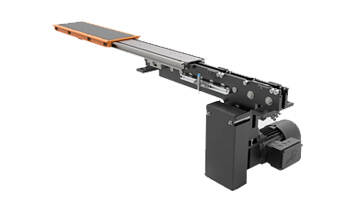

Fork telescópico único

Os garfos de alcance único são uma solução inovadora de manuseio de materiais projetada para operações eficientes de armazenamento e recuperação em ambientes de armazém. Com uma estrutura simples, mas eficaz de três peças, esses garfos podem penetrar profundamente em uma única baía de rack, oferecendo manuseio preciso de carga. O design do garfo de alcance único é adaptado para a estilhagem de paletes de profundidade padrão, otimizando a utilização do espaço do armazém e a eficiência operacional.

Fork telescópico de duplo profundidade

Os garfos de alcance duplo são equipamentos avançados de armazém de alcance duplo, projetados para manuseio de materiais de alta eficiência em sistemas de estantes de alcance profundo. Esses garfos oferecem uma capacidade de extensão dupla, quase dobrando o alcance dos garfos de alcance único tradicional, tornando-os ideais para acessar e recuperar itens de posições de armazenamento mais profundas.